ANDON RAPIDCALL SYSTEM

The Andon system is a crucial component of Lean manufacturing, initially developed to notify operators of any issues on the production line. Originating from the Toyota Production System (TPS), it serves as a mechanism to halt production immediately upon detecting a product defect. Stemming from the Jidoka concept in Lean, which encourages employees to halt production when a quality issue arises, Andon has evolved into a vital tool for ensuring product quality and process efficiency.

This system operates as a continuous monitoring tool, swiftly detecting, notifying, and alerting personnel to any anomalies during production. Its versatility is evident in its various forms, ranging from single-machine alerts to alerts spanning multiple assembly lines and stages. These alerts can range from simple light or bell notifications to more complex board formats, ensuring prompt action and resolution of production issues.

1. Andon RapidCall System Introduction

The Andon RapidCall system is a real-time production monitoring system that seamlessly integrates hardware and software components. It detects abnormalities during the production process and promptly alerts responsible personnel to issues such as maintenance requirements, staffing or resource needs, and quality concerns. This enables timely resolution to prevent production interruptions and maintain product quality standards.

Andon RapidCall enhances control throughout the production process, improves operational efficiency, and enhances product quality. It achieves these objectives by optimizing the utilization of machinery and labor, thereby minimizing costs while maximizing productivity.

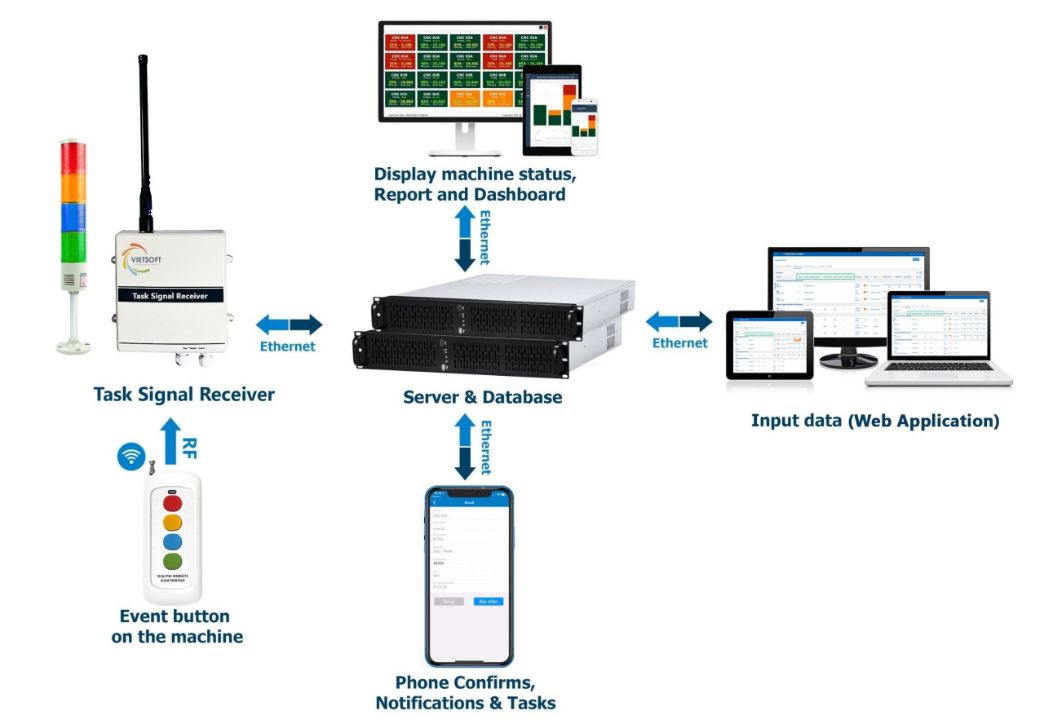

2. Andon RapidCall System Structure

Hardware:

Server;

Smart TV;

- Tablet/PC/Laptop

- Task Signal Receiver

- Event Button

Software:

- Integration Module runs on Server

- Web App runs on Smart TV

- Web APP runs on Tablet / Desktop/Laptop/

- Smartphone (Android/IOS)

- Mobile Application runs on Mobile phone

3. Andon RapidCall System benefits

- Enhancing Responsiveness and Reducing Downtime: The ANDON RapidCall system allows employees to immediately report any issues by pressing the ANDON RapidCall button or using the software. This enables technical staff to take precise actions to address the problem promptly, minimizing downtime and preventing disruptions in the production process.

- Quality Control: The ANDON RapidCall system helps limit defective products, thereby improving the overall quality of the products.

- Continuous Improvement: The system continually updates and provides feedback on production data, enabling technical staff to make appropriate improvements to the production process.

- Improving Communication Between Production Departments: Furthermore, the ANDON system enhances interaction and information exchange between producting employees and different production units.

- Cost Savings in Production: The ANDON RapidCall system optimizes the production process, minimizing machine downtime. Additionally, it saves costs on repairs and replacements, reduces maintenance expenses, and enhances operational efficiency for the production system.

- Ensuring Production Safety: The ANDON RapidCall system ensures safety for employees during production, minimizing workplace accidents and other risks. With this system, employees can quickly detect issues and implement corrective measures, ensuring maximum production efficiency and productivity

4. Brochure of Andon RapidCall System